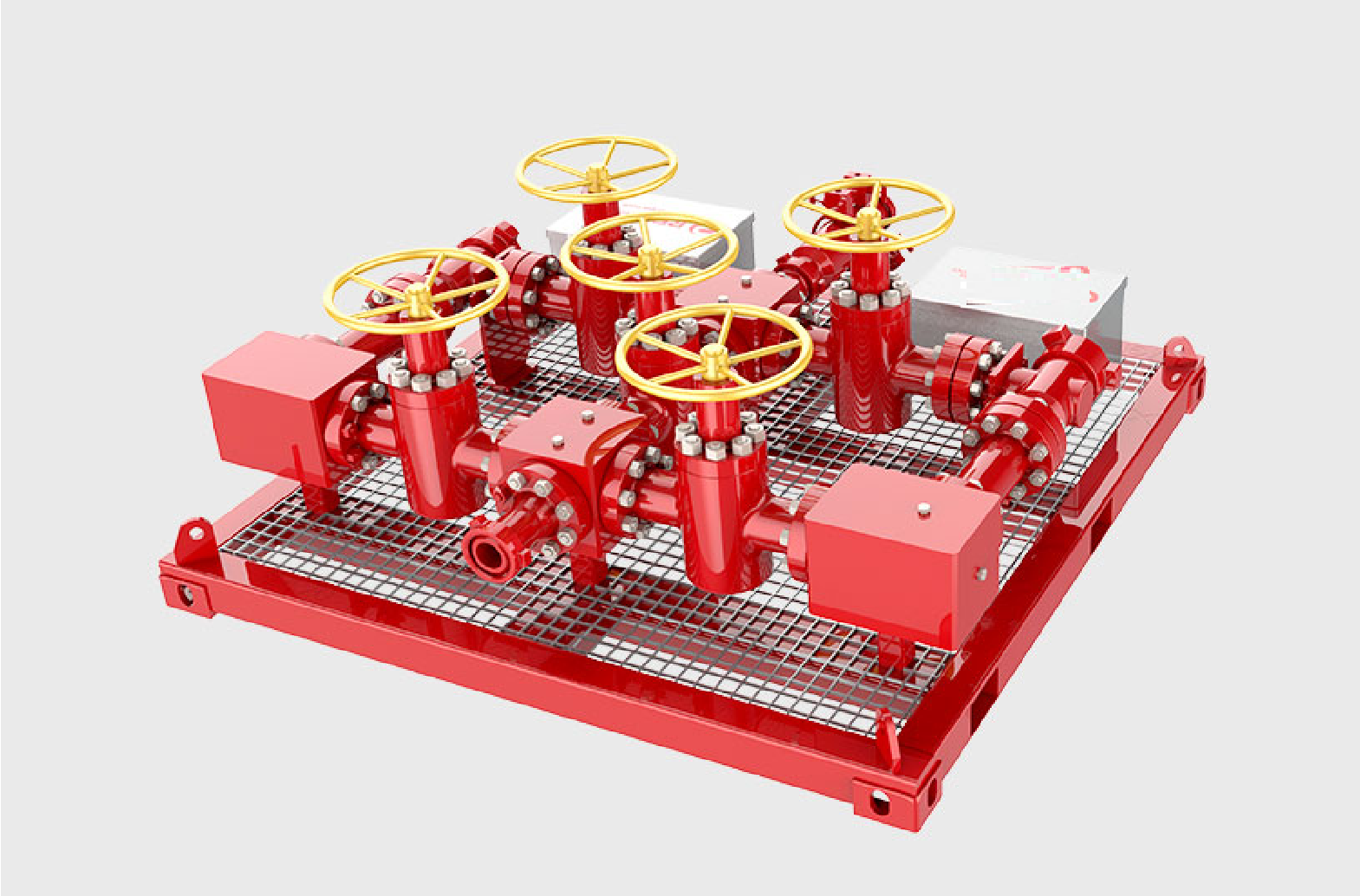

Heater Treaters

Description

The Heater Treaters are combined equipment aiming to dehydrate (or dewater) the produced crude oil to a specified level of Basic Sediment and Water (BS&W). Incoming Emulsion enters the vessel by the top. The emulsion flows over the fire tube shroud where it is heated to the desired temperature (The heated water serves to wash the emulsion and to aid in the coalescing of the water droplets). The emulsion and oil continue to rise into the oil treating compartment of the vessel where the emulsion breaking process continues -optionally by using electrostatic grids- . The clean oil exits the vessel near the top of the vessel and the water is drawn off directly under the emulsion distribution pan

Applications

- Early and Permanent Production Facilities

- Crude treatment and Desalting facilities

Technical Specifications:

- Heating Capacity: 1 mmbtu/hr up to 6 mmbtu/hr

- Vessel Working Pressure (psi) : 50 psi up to 250 psi

- Design Code and Material Compliance : API12J / ASME VIII div.1 / ANSI B31-3., NACE MR-0175

- Burner Type ( Fuel ): Heavy duty Gas Fired Burner or Diesel Fired Burner

- Optional : Vessel insulation , Automation & control options